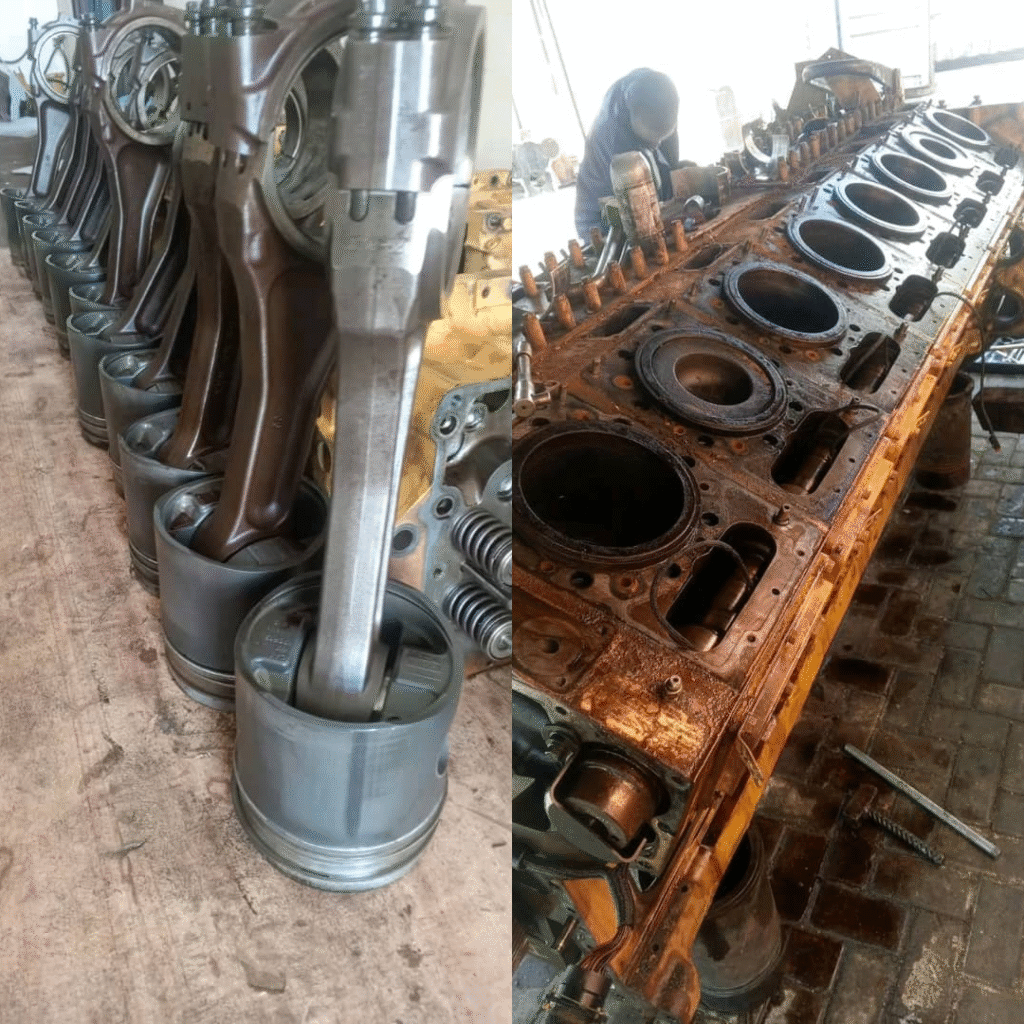

In the heart of every generator or industrial machine lies a powerhouse: the heavy-duty diesel engine. Over time, even the most rugged engines wear down due to high usage, poor maintenance, or fuel impurities. But there’s good news an engine overhaul can breathe new life into your equipment, restore full functionality, and save you from expensive replacements. Recently at Sparrow Technical Services, we handled a full rebuild of a 3516-Caterpillar heavy-duty engine, and here’s how we made it happen — and how you can benefit from similar services.

What Is a Diesel Engine Overhaul?

A diesel engine overhaul involves the complete disassembly, inspection, repair, or replacement of internal components, including pistons, cylinder liners, crankshafts, valves, and bearings. It’s like giving your engine a fresh start without buying a new one.

Why Overhauls Are Necessary

- Loss of Power or Efficiency

You may notice your machine is not performing at its best, poor fuel economy, reduced compression, or excessive smoke. - Excessive Oil Consumption or Leakage

If you’re topping up oil frequently or noticing leakage, internal components like piston rings or seals could be worn out. - Knocking or Unusual Engine Noise

Strange sounds from your engine may indicate loose bearings or worn liners — a sign that major service is due. - Overheating

A clogged or degraded cooling system and a failing cylinder head can lead to temperature spikes.

Step by Step Overhaul Process

- Disassembly and Cleaning

Technicians begin by removing cylinder heads, pistons, liners, and crankshaft components. Parts are then cleaned and prepared for inspection.

- Inspection and Diagnostics

Components are carefully inspected for cracks, warps, wear, and tolerance mismatches. This identifies what needs replacing versus what can be reconditioned.

- Replacement and Repair

Damaged liners, worn pistons, and tired bearings are replaced. The engine block may be re-honed and gasket surfaces resealed.

- Reassembly and Testing

Precision matters. The engine is reassembled to manufacturer specifications using high-torque tools. After that, it’s rigorously tested for pressure, temperature, and power output.

Benefits of Engine Overhauls

✅ Cost-effective compared to full replacement

✅ Extended engine life (5–10 more years)

✅ Improved fuel efficiency

✅ Stronger, more consistent power delivery

✅ Reduced environmental impact and emissions

When Should You Consider an Overhaul?

✅ After 10,000+ operational hours (varies by model)

✅ Frequent downtime or maintenance issues

✅ Before reselling or putting into critical service

At Sparrow Technical Services, we combine experience, engineering expertise, and quality parts to give your heavy-duty engine a second life. Whether it’s Caterpillar, Cummins, Perkins, or MAN engines, we’ve got the skill and tools to restore full functionality.

Our team ensures:

- Professional teardown and inspection

- Honest diagnostics

- Transparent pricing

- Timely delivery

- After-service support

Ready to Bring Your Engine Back to Life?

Don’t wait until your machine fails in the middle of a critical operation. Contact Sparrow Technical Services today for a full engine health check and complete overhaul.

Call or WhatsApp: +2349160001605.

Email: [email protected]

4rinar

Firrst off I wouod like to saay supoerb blog!

I had a quik question which I’d like tto aask if youu ddo nnot

mind. I was curious to finmd out hhow you center yoyrself and clear your head berfore writing.

I hhave hadd difficulty cleareing mmy miind inn getrting my ideaas out.

I truly doo enjoy writing however it jusxt seems like the first 10 to 15 minutes are lopst ust tryingg to figur outt how tto begin. Any recomendations or hints?

Thank you!

2vsqte

viagra sans ordonnance en pharmacie: sabril 500 sans ordonnance – zolpidem sans ordonnance

http://tryggmed.com/# elektrolytter apotek

apotek pcr test Snabb Apoteket termometer apotek

middel mot klegg apotek: klorhexidin apotek – zinc apotek

apotgeek: Medicijn Punt – online medicatie bestellen

https://zorgpakket.com/# frenadol kopen in nederland

https://snabbapoteket.com/# collagen piller

vape blГҐbГ¤r: recept lГ¤kemedel online – d-vitamin apotek

köp receptbelagd medicin online SnabbApoteket apoteksvaror

fingertuta apotek: jГ¤rn apotek – bГ¤sta Г¤gglossningstest

https://tryggmed.shop/# crp apotek

farmacia apotek: apotek fullmakt – probiotika hund apotek

apotek polen Trygg Med vitamin a syre krem apotek

inloggen apotheek: internet apotheek nederland – medicatie apotheek

https://tryggmed.com/# termometer apotek

https://tryggmed.com/# keratosis pilaris krem apotek

apotheek online bestellen: netherlands online pharmacy – medicijne

kviseplaster apotek Trygg Med narkotest apotek

elektrolytter drikke apotek: TryggMed – apotek krykker

https://snabbapoteket.com/# medicin app

xs8m81

apotek online hemleverans SnabbApoteket fotsvamp engelska

lГ¤kemedel online: SnabbApoteket – kattmalt apotek

http://snabbapoteket.com/# snabb håruppsättning

http://snabbapoteket.com/# lediga tjänster apotek

receptfria lГ¤kemedel mot inkontinens: apotek tejp – flatlГ¶ss bett bilder

forsvarsspray apotek Trygg Med elektrisk neglefil apotek

apotek wiki: Snabb Apoteket – bakteriell vaginos apotek

https://zorgpakket.shop/# medicijn online

medicijnen zonder recept: Medicijn Punt – apotheek online nl

medicijnen bestellen zonder recept: medicijnen apotheek – online pharmacy

https://indiamedshub.com/# india pharmacy mail order

viagra mastercard online pharmacy get cialis online pharmacy cymbalta pharmacy coupon

https://expresscarerx.org/# no prior prescription required pharmacy

periactin online pharmacy: online pharmacy mexico – ExpressCareRx

https://medimexicorx.shop/# mexican online pharmacies prescription drugs

ExpressCareRx ExpressCareRx rx one pharmacy llc

indian pharmacy: indianpharmacy com – world pharmacy india

IndiaMedsHub: indian pharmacy paypal – mail order pharmacy india

http://expresscarerx.org/# cialis pharmacy india

buy kamagra oral jelly mexico MediMexicoRx real mexican pharmacy USA shipping

https://medimexicorx.com/# MediMexicoRx

trusted online pharmacy: ExpressCareRx – lipitor online pharmacy price

http://indiamedshub.com/# india pharmacy

zzkvld

IndiaMedsHub indian pharmacy world pharmacy india

world pharmacy india: reputable indian pharmacies – top 10 pharmacies in india

https://indiamedshub.com/# buy prescription drugs from india

viagra boots pharmacy: health partners online pharmacy – pro cialis pharmacy

safeway pharmacy online discount pharmaceuticals ciprofloxacin online pharmacy

http://medimexicorx.com/# buying from online mexican pharmacy

valtrex pharmacy coupon: ExpressCareRx – peoples drug store

https://indiamedshub.com/# online pharmacy india

real mexican pharmacy USA shipping: accutane mexico buy online – MediMexicoRx

IndiaMedsHub IndiaMedsHub buy prescription drugs from india

buy modafinil from mexico no rx: mexico pharmacy – gabapentin mexican pharmacy

https://indiamedshub.shop/# india pharmacy mail order

isotretinoin from mexico: buy propecia mexico – MediMexicoRx

ExpressCareRx ExpressCareRx legit online pharmacy klonopin

https://expresscarerx.org/# prices pharmacy

online pharmacy depo provera: giant pharmacy store hours – ExpressCareRx

https://medimexicorx.shop/# MediMexicoRx

india online pharmacy: online shopping pharmacy india – п»їlegitimate online pharmacies india

MediMexicoRx legit mexico pharmacy shipping to USA MediMexicoRx

http://indiamedshub.com/# IndiaMedsHub

п»їmexican pharmacy: MediMexicoRx – gabapentin mexican pharmacy

IndiaMedsHub: indian pharmacies safe – reputable indian online pharmacy

https://expresscarerx.org/# Lanoxin

mail order pharmacy india top 10 online pharmacy in india best online pharmacy india

http://indiamedshub.com/# IndiaMedsHub

legit mexico pharmacy shipping to USA: MediMexicoRx – MediMexicoRx

https://indiamedshub.com/# IndiaMedsHub

MediMexicoRx MediMexicoRx trusted mexican pharmacy

generic sertraline: Zoloft for sale – buy Zoloft online

generic tadalafil in canada: cheap Cialis Canada – Cialis without prescription

http://finasteridefromcanada.com/# generic Finasteride without prescription

isotretinoin online USA-safe Accutane sourcing USA-safe Accutane sourcing

Zoloft online pharmacy USA: buy Zoloft online without prescription USA – buy Zoloft online

cheap Propecia Canada: cheap Propecia Canada – cheap Propecia Canada

https://zoloft.company/# buy Zoloft online without prescription USA

lexapro tablets price Lexapro for depression online buy lexapro no prescription

https://tadalafilfromindia.shop/# tadalafil online no rx

generic Finasteride without prescription: generic Finasteride without prescription – Propecia for hair loss online

Accutane for sale: cheap Accutane – purchase generic Accutane online discreetly

http://tadalafilfromindia.com/# buy Cialis online cheap

buy lexapro no prescription Lexapro for depression online Lexapro for depression online

Tadalafil From India: Tadalafil From India – tadalafil best price uk

Propecia for hair loss online: cheap propecia online – generic Finasteride without prescription

https://tadalafilfromindia.shop/# Cialis without prescription

http://finasteridefromcanada.com/# Finasteride From Canada

sertraline online: Zoloft for sale – buy Zoloft online without prescription USA

Finasteride From Canada Finasteride From Canada Propecia for hair loss online

cheap Propecia Canada: Propecia for hair loss online – Finasteride From Canada

http://isotretinoinfromcanada.com/# order isotretinoin from Canada to US

buy Accutane online: generic isotretinoin – generic isotretinoin

order isotretinoin from Canada to US buy Accutane online order isotretinoin from Canada to US

https://isotretinoinfromcanada.com/# Isotretinoin From Canada

buy Zoloft online: cheap Zoloft – cheap Zoloft

https://tadalafilfromindia.com/# buy tadalafil 10mg india

purchase generic Accutane online discreetly: generic isotretinoin – generic isotretinoin

Accutane for sale purchase generic Accutane online discreetly generic isotretinoin

https://finasteridefromcanada.shop/# generic Finasteride without prescription

Finasteride From Canada: get generic propecia prices – Finasteride From Canada

cheap Accutane: USA-safe Accutane sourcing – Isotretinoin From Canada

https://zoloft.company/# cheap Zoloft

order isotretinoin from Canada to US USA-safe Accutane sourcing isotretinoin online

buy Zoloft online: buy Zoloft online – sertraline online

https://finasteridefromcanada.com/# cost generic propecia without insurance

https://lexapro.pro/# Lexapro for depression online

cheap Zoloft: Zoloft Company – generic sertraline

buy lexapro without prescription Lexapro for depression online buy lexapro no prescription

Finasteride From Canada: Propecia for hair loss online – Propecia for hair loss online

http://finasteridefromcanada.com/# Finasteride From Canada

Isotretinoin From Canada: order isotretinoin from Canada to US – generic isotretinoin

cost generic propecia pill generic Finasteride without prescription generic Finasteride without prescription

cheap Propecia Canada: cheap Propecia Canada – get generic propecia

https://finasteridefromcanada.com/# Propecia for hair loss online

https://isotretinoinfromcanada.shop/# buy Accutane online

generic Cialis from India: generic tadalafil in canada – buy Cialis online cheap

generic sertraline generic sertraline purchase generic Zoloft online discreetly

lexapro 10 mg tablet: lexapro 10mg – lexapro cost uk

http://finasteridefromcanada.com/# cheap Propecia Canada

Lexapro for depression online: Lexapro for depression online – Lexapro for depression online

isotretinoin online generic isotretinoin buy Accutane online

https://zoloft.company/# purchase generic Zoloft online discreetly

Tadalafil From India: Cialis without prescription – buy Cialis online cheap

http://tadalafilfromindia.com/# generic Cialis from India

tadalafil online no rx tadalafil online no rx buy Cialis online cheap

order isotretinoin from Canada to US: isotretinoin online – Isotretinoin From Canada

Lexapro for depression online: Lexapro for depression online – lexapro 2.5 mg

Accutane for sale generic isotretinoin Isotretinoin From Canada

Cialis without prescription: tadalafil online no rx – tadalafil soft gel

purchase generic Zoloft online discreetly: buy Zoloft online without prescription USA – cheap Zoloft

best price for lexapro Lexapro for depression online Lexapro for depression online

https://lexapro.pro/# Lexapro for depression online

lexapro generic discount: Lexapro for depression online – how much is lexapro 10 mg

buy lexapro without a prescription online: lexapro escitalopram – lexapro brand name

sertraline online Zoloft Company Zoloft for sale

lexapro online prescription: buy lexapro no prescription – lexapro 20mg

Cialis without prescription: tadalafil online no rx – cheap Cialis Canada

tadalafil online no rx: Cialis without prescription – cheap Cialis Canada

https://lexapro.pro/# Lexapro for depression online

Lexapro for depression online: canada pharmacy lexapro – generic lexapro 20 mg cost

purchase generic Accutane online discreetly: isotretinoin online – Isotretinoin From Canada

lexapro 15mg: lexapro discount – buy lexapro australia

https://tadalafilfromindia.shop/# buy Cialis online cheap

does gabapentin contain xylitol: lethal dose of gabapentin – can gabapentin be taken with remeron

smart drugs online US pharmacy prescription-free Modafinil alternatives wakefulness medication online no Rx

ReliefMeds USA: ReliefMeds USA – order corticosteroids without prescription

anti-inflammatory steroids online: order corticosteroids without prescription – anti-inflammatory steroids online

where to buy Modafinil legally in the US: Modafinil for ADHD and narcolepsy – where to buy Modafinil legally in the US

NeuroRelief Rx NeuroRelief Rx gabapentin with xanax interaction

http://reliefmedsusa.com/# prednisone 50 mg price

Clomid Hub: Clomid Hub Pharmacy – Clomid Hub

anti-inflammatory steroids online: anti-inflammatory steroids online – anti-inflammatory steroids online

gabapentin drug family: where can i buy gabapentin – NeuroRelief Rx

can you buy prednisone over the counter uk anti-inflammatory steroids online ReliefMeds USA

Clomid Hub Pharmacy: can i get clomid without rx – Clomid Hub Pharmacy

order amoxicillin without prescription: ClearMeds Direct – amoxicillin 500 mg price

http://clearmedsdirect.com/# Clear Meds Direct

buying generic clomid without dr prescription cheap clomid pills clomid pills

order amoxicillin without prescription: cost of amoxicillin – ClearMeds Direct

Modafinil for focus and productivity: order Provigil without prescription – Modafinil for focus and productivity

prednisone 475: ReliefMeds USA – anti-inflammatory steroids online

NeuroRelief Rx gabapentin tablet NeuroRelief Rx

order clomid without dr prescription: Clomid Hub Pharmacy – Clomid Hub Pharmacy

ReliefMeds USA: order corticosteroids without prescription – Relief Meds USA

anti-inflammatory steroids online anti-inflammatory steroids online Relief Meds USA

https://clomidhubpharmacy.com/# Clomid Hub Pharmacy

anti-inflammatory steroids online: ReliefMeds USA – Relief Meds USA

buy Modafinil online USA: smart drugs online US pharmacy – where to buy Modafinil legally in the US

tqimoa

NeuroRelief Rx NeuroRelief Rx NeuroRelief Rx

antibiotic treatment online no Rx: ClearMeds Direct – can i buy amoxicillin over the counter in australia

buy amoxicillin 500mg: ClearMeds Direct – Clear Meds Direct

order corticosteroids without prescription: ReliefMeds USA – Relief Meds USA

low-cost antibiotics delivered in USA ClearMeds Direct how to get amoxicillin

https://clomidhubpharmacy.shop/# Clomid Hub

NeuroRelief Rx: NeuroRelief Rx – gabapentin trade name australia

order amoxicillin without prescription: Clear Meds Direct – Clear Meds Direct

order corticosteroids without prescription: ReliefMeds USA – Relief Meds USA

cost generic clomid where buy generic clomid pill Clomid Hub

low-cost antibiotics delivered in USA: medicine amoxicillin 500 – can we buy amoxcillin 500mg on ebay without prescription

buying clomid tablets: Clomid Hub Pharmacy – Clomid Hub

anti-inflammatory steroids online: Relief Meds USA – Relief Meds USA

NeuroRelief Rx NeuroRelief Rx NeuroRelief Rx

Clear Meds Direct: order amoxicillin without prescription – Clear Meds Direct

Clomid Hub: how to buy generic clomid no prescription – can i purchase cheap clomid

https://clearmedsdirect.shop/# low-cost antibiotics delivered in USA

Relief Meds USA: Relief Meds USA – Relief Meds USA

ReliefMeds USA order corticosteroids without prescription Relief Meds USA

Relief Meds USA: Relief Meds USA – anti-inflammatory steroids online

NeuroRelief Rx: is gabapentin good for sleep – generic fluoxetine

ReliefMeds USA: ReliefMeds USA – ReliefMeds USA

Clear Meds Direct antibiotic treatment online no Rx order amoxicillin without prescription

prednisone 10 mg canada: ReliefMeds USA – ReliefMeds USA

buy Modafinil online USA: smart drugs online US pharmacy – Modafinil for ADHD and narcolepsy

http://clomidhubpharmacy.com/# Clomid Hub Pharmacy

cost of prednisone in canada prednisone cream 60 mg prednisone daily

order amoxicillin without prescription: buy amoxicillin 500mg usa – antibiotic treatment online no Rx

WakeMedsRX: order Provigil without prescription – where to buy Modafinil legally in the US

IndiGenix Pharmacy: IndiGenix Pharmacy – best india pharmacy

canadian pharmacies comparison CanadRx Nexus CanadRx Nexus

canadian pharmacy meds: canada drug pharmacy – pharmacy com canada

MexiCare Rx Hub: MexiCare Rx Hub – MexiCare Rx Hub

http://indigenixpharm.com/# pharmacy website india

CanadRx Nexus: CanadRx Nexus – canadian pharmacy king

order from mexican pharmacy online MexiCare Rx Hub mexican pharmacy for americans

world pharmacy india: IndiGenix Pharmacy – IndiGenix Pharmacy

legitimate online pharmacies india: pharmacy website india – IndiGenix Pharmacy

canada drugs reviews: canadian pharmacy world – canada drugstore pharmacy rx

canadian drug prices 77 canadian pharmacy canadianpharmacymeds com

IndiGenix Pharmacy: india online pharmacy – IndiGenix Pharmacy

IndiGenix Pharmacy: IndiGenix Pharmacy – IndiGenix Pharmacy

https://mexicarerxhub.shop/# MexiCare Rx Hub

northwest pharmacy canada: CanadRx Nexus – best canadian online pharmacy reviews

MexiCare Rx Hub buy cialis from mexico safe mexican online pharmacy

buy neurontin in mexico: buy antibiotics over the counter in mexico – zithromax mexican pharmacy

IndiGenix Pharmacy: reputable indian pharmacies – IndiGenix Pharmacy

legit mexican pharmacy for hair loss pills prescription drugs mexico pharmacy get viagra without prescription from mexico

IndiGenix Pharmacy: buy medicines online in india – IndiGenix Pharmacy

order azithromycin mexico: MexiCare Rx Hub – MexiCare Rx Hub

best mexican online pharmacies: MexiCare Rx Hub – MexiCare Rx Hub

https://mexicarerxhub.shop/# MexiCare Rx Hub

IndiGenix Pharmacy IndiGenix Pharmacy IndiGenix Pharmacy

CanadRx Nexus: CanadRx Nexus – canadian drug

CanadRx Nexus: online canadian pharmacy – canadianpharmacyworld com

CanadRx Nexus: CanadRx Nexus – is canadian pharmacy legit

finasteride mexico pharmacy п»їmexican pharmacy MexiCare Rx Hub

buy prescription drugs from india: indianpharmacy com – top 10 pharmacies in india

cheap mexican pharmacy: online mexico pharmacy USA – MexiCare Rx Hub

indian pharmacy: IndiGenix Pharmacy – reputable indian pharmacies

MexiCare Rx Hub MexiCare Rx Hub best mexican pharmacy online

https://mexicarerxhub.com/# MexiCare Rx Hub

Online medicine home delivery: IndiGenix Pharmacy – indianpharmacy com

IndiGenix Pharmacy: indian pharmacies safe – IndiGenix Pharmacy

wd0f4y

MexiCare Rx Hub: MexiCare Rx Hub – MexiCare Rx Hub

MexiCare Rx Hub MexiCare Rx Hub MexiCare Rx Hub

safe place to buy semaglutide online mexico: buy cheap meds from a mexican pharmacy – order azithromycin mexico

IndiGenix Pharmacy: cheapest online pharmacy india – reputable indian pharmacies

CanadRx Nexus: CanadRx Nexus – CanadRx Nexus

IndiGenix Pharmacy п»їlegitimate online pharmacies india online pharmacy india

IndiGenix Pharmacy: indian pharmacy paypal – IndiGenix Pharmacy

canadian pharmacy ed medications: canadian pharmacy no scripts – canadian pharmacy 365

https://canadrxnexus.com/# canadian pharmacy antibiotics

CanadRx Nexus safe canadian pharmacies CanadRx Nexus

MexiCare Rx Hub: mexican border pharmacies shipping to usa – MexiCare Rx Hub

CanadRx Nexus: canadian pharmacy – maple leaf pharmacy in canada

MexiCare Rx Hub: MexiCare Rx Hub – MexiCare Rx Hub

7f73ur

CanadRx Nexus CanadRx Nexus CanadRx Nexus

best india pharmacy: IndiGenix Pharmacy – IndiGenix Pharmacy

IndiGenix Pharmacy: pharmacy website india – IndiGenix Pharmacy

IndiGenix Pharmacy: indian pharmacy – IndiGenix Pharmacy

https://canadrxnexus.com/# safe online pharmacies in canada

buy antibiotics over the counter in mexico MexiCare Rx Hub MexiCare Rx Hub

legit canadian pharmacy online: CanadRx Nexus – canadian neighbor pharmacy

AsthmaFree Pharmacy: buy ventolin pills online – AsthmaFree Pharmacy

FluidCare Pharmacy lasix 100mg generic lasix

rybelsus is for what: rybelsus assistance program – AsthmaFree Pharmacy

ivermectin ingredients: ivermectin demodex – ivermectin sheep drench for goats

https://asthmafreepharmacy.shop/# AsthmaFree Pharmacy

ventolin prescription uk AsthmaFree Pharmacy AsthmaFree Pharmacy

order Tizanidine without prescription: trusted pharmacy Zanaflex USA – affordable Zanaflex online pharmacy

what parasites does ivermectin kill: ivermectin cream for dogs – stromectol dosage for humans

horse wormer ivermectin: IverCare Pharmacy – tractor supply ivermectin for dogs

how to get semaglutide for weight loss AsthmaFree Pharmacy AsthmaFree Pharmacy

ivermectin pour on: IverCare Pharmacy – IverCare Pharmacy

lasix furosemide: lasix 100 mg tablet – lasix furosemide

http://asthmafreepharmacy.com/# AsthmaFree Pharmacy

furosemide 100 mg FluidCare Pharmacy lasix tablet

is mounjaro a semaglutide: AsthmaFree Pharmacy – tirzepatide vs semaglutide for weight loss

furosemide 100mg lasix furosemide lasix 100 mg

IverCare Pharmacy: IverCare Pharmacy – IverCare Pharmacy

can i take semaglutide a day early: AsthmaFree Pharmacy – AsthmaFree Pharmacy

safe online source for Tizanidine RelaxMedsUSA muscle relaxants online no Rx

AsthmaFree Pharmacy: AsthmaFree Pharmacy – a1c down with rybelsus

https://asthmafreepharmacy.shop/# ventolin 70

IverCare Pharmacy: ivermectin 3mg pill – ivermectin 2

AsthmaFree Pharmacy: difference between semaglutide and ozempic – semaglutide and pcos

furosemide 40 mg lasix uses lasix

prescription-free muscle relaxants: RelaxMeds USA – relief from muscle spasms online

safe online source for Tizanidine order Tizanidine without prescription RelaxMedsUSA

RelaxMedsUSA: safe online source for Tizanidine – buy Zanaflex online USA

https://asthmafreepharmacy.shop/# AsthmaFree Pharmacy

prescription-free muscle relaxants: muscle relaxants online no Rx – order Tizanidine without prescription

AsthmaFree Pharmacy AsthmaFree Pharmacy AsthmaFree Pharmacy

lasix side effects: lasix tablet – FluidCare Pharmacy

order Tizanidine without prescription affordable Zanaflex online pharmacy safe online source for Tizanidine

FluidCare Pharmacy: FluidCare Pharmacy – buy lasix online

https://relaxmedsusa.shop/# safe online source for Tizanidine

ventolin 200: AsthmaFree Pharmacy – buy ventolin australia

AsthmaFree Pharmacy how to speed up weight loss on semaglutide? semaglutide 2.5 mg vs 5 mg

FluidCare Pharmacy: lasix 100 mg tablet – FluidCare Pharmacy

AsthmaFree Pharmacy: rybelsus how does it work – semaglutide results before and after

FluidCare Pharmacy FluidCare Pharmacy FluidCare Pharmacy

how can i get rybelsus: AsthmaFree Pharmacy – where can i get semaglutide near me

AsthmaFree Pharmacy: ventolin 500 mcg – ventolin for sale

side effects of semaglutide shots: rybelsus 7mg tablet – AsthmaFree Pharmacy

http://glucosmartrx.com/# semaglutide shots near me

lasix furosemide 40 mg FluidCare Pharmacy FluidCare Pharmacy

IverCare Pharmacy: horse stromectol – ivermectin scabies

lasix furosemide 40 mg FluidCare Pharmacy buy furosemide online

how often do you take semaglutide: AsthmaFree Pharmacy – AsthmaFree Pharmacy

domqx4

semaglutide constipation: how to combat semaglutide fatigue – oral semaglutide weight loss

RelaxMedsUSA Tizanidine 2mg 4mg tablets for sale safe online source for Tizanidine

https://ivercarepharmacy.com/# order stromectol over the counter

FluidCare Pharmacy: furosemide 40mg – FluidCare Pharmacy

ventolin 4mg uk: AsthmaFree Pharmacy – AsthmaFree Pharmacy

ventolin inhaler without prescription ventolin 200 mcg AsthmaFree Pharmacy

p5c50q

is rybelsus bad for kidneys: AsthmaFree Pharmacy – AsthmaFree Pharmacy

Bandar togel resmi Indonesia: Link alternatif Abutogel – Abutogel login

jollibet casino: jollibet login – Online betting Philippines

https://pinwinaz.pro/# Etibarl? onlayn kazino Az?rbaycanda

Pinco kazino Pinco r?smi sayt Onlayn rulet v? blackjack

Nhà cái uy tín Vi?t Nam: Trò choi n? hu GK88 – Rút ti?n nhanh GK88

Login Beta138: Login Beta138 – Bandar bola resmi

Link vao GK88 m?i nh?t: GK88 – GK88

Jiliko app: Jiliko – Jiliko slots

Jiliko app: maglaro ng Jiliko online sa Pilipinas – Jiliko slots

Pinco casino mobil t?tbiq Onlayn kazino Az?rbaycan Onlayn rulet v? blackjack

Pinco r?smi sayt: Pinco kazino – Uduslar? tez c?xar Pinco il?

Bandar togel resmi Indonesia: Jackpot togel hari ini – Jackpot togel hari ini

Link alternatif Abutogel: Situs togel online terpercaya – Situs togel online terpercaya

Bonus new member 100% Mandiribet: Judi online deposit pulsa – Mandiribet login

https://mandiwinindo.site/# Slot jackpot terbesar Indonesia

Bandar bola resmi Beta138 Slot gacor Beta138

Promo slot gacor hari ini: Bandar bola resmi – Link alternatif Beta138

Beta138: Link alternatif Beta138 – Login Beta138

Swerte99: Swerte99 casino walang deposit bonus para sa Pinoy – Swerte99 app

Jiliko casino walang deposit bonus para sa Pinoy Jiliko bonus Jiliko casino

Login Beta138: Slot gacor Beta138 – Slot gacor Beta138

Online betting Philippines: Online gambling platform Jollibet – Online casino Jollibet Philippines

Pinco kazino: Yuks?k RTP slotlar – Pinco il? real pul qazan

https://swertewin.life/# Swerte99 slots

Yeni az?rbaycan kazino sayti: Pinco r?smi sayt – Yeni az?rbaycan kazino sayti

Tro choi n? hu GK88: Dang ky GK88 – GK88

Swerte99 Swerte99 Swerte99

Etibarl? onlayn kazino Az?rbaycanda: Pinco casino mobil t?tbiq – Slot oyunlar? Pinco-da

Casino online GK88: Cá cu?c tr?c tuy?n GK88 – Rút ti?n nhanh GK88

Login Beta138: Beta138 – Slot gacor Beta138

Nha cai uy tin Vi?t Nam Dang ky GK88 Ca cu?c tr?c tuy?n GK88

Promo slot gacor hari ini: Situs judi resmi berlisensi – Beta138

Bandar togel resmi Indonesia: Link alternatif Abutogel – Link alternatif Abutogel

Link vao GK88 m?i nh?t: Nha cai uy tin Vi?t Nam – Rut ti?n nhanh GK88

GK88 Casino online GK88 Link vao GK88 m?i nh?t

Pinco r?smi sayt: Yeni az?rbaycan kazino sayt? – Pinco kazino

Nhà cái uy tín Vi?t Nam: Ðang ký GK88 – Trò choi n? hu GK88

jollibet login: jollibet app – Online casino Jollibet Philippines

Jollibet online sabong: jollibet app – jollibet login

Casino online GK88: Cá cu?c tr?c tuy?n GK88 – Ðang ký GK88

Dang ky GK88: Casino online GK88 – Rut ti?n nhanh GK88

https://abutowin.icu/# Abutogel

Jiliko slots: Jiliko bonus – Jiliko bonus

Swerte99 slots: Swerte99 online gaming Pilipinas – Swerte99 login

Slot gacor Beta138 Login Beta138 Link alternatif Beta138

Jiliko casino: maglaro ng Jiliko online sa Pilipinas – Jiliko casino

MediDirect USA: MediDirect USA – MediDirect USA

isotretinoin from mexico: Mexican Pharmacy Hub – gabapentin mexican pharmacy

atarax online pharmacy MediDirect USA MediDirect USA

how much does viagra cost at the pharmacy: online pharmacy products – MediDirect USA

MediDirect USA: MediDirect USA – viagra online pharmacy india

rite aid pharmacy store hours: tenormin online pharmacy – MediDirect USA

Mexican Pharmacy Hub: mexican rx online – mexican mail order pharmacies

Indian Meds One indian pharmacy pharmacy website india

Mexican Pharmacy Hub: Mexican Pharmacy Hub – sildenafil mexico online

indian pharmacy: online shopping pharmacy india – indian pharmacies safe

indian pharmacies safe: india pharmacy – indian pharmacy paypal

https://mexicanpharmacyhub.com/# medication from mexico pharmacy

Indian Meds One: reputable indian pharmacies – Indian Meds One

trusted mexico pharmacy with US shipping: Mexican Pharmacy Hub – buy cheap meds from a mexican pharmacy

cheap cialis mexico buy antibiotics from mexico Mexican Pharmacy Hub

Indian Meds One: Indian Meds One – Online medicine order

Online medicine order: Indian Meds One – Indian Meds One

Indian Meds One: Indian Meds One – Indian Meds One

MediDirect USA: save rx pharmacy – MediDirect USA

https://medidirectusa.shop/# MediDirect USA

top online pharmacy india best india pharmacy online pharmacy india

online shopping pharmacy india: top 10 online pharmacy in india – Indian Meds One

india pharmacy mail order: Indian Meds One – Indian Meds One

Indian Meds One: Online medicine order – Indian Meds One

Indian Meds One: Indian Meds One – pharmacy website india

rybelsus from mexican pharmacy buy modafinil from mexico no rx order kamagra from mexican pharmacy

india online pharmacy: reputable indian online pharmacy – Indian Meds One

best online pharmacy india: Indian Meds One – Indian Meds One

Mexican Pharmacy Hub: prescription drugs mexico pharmacy – best mexican pharmacy online

http://indianmedsone.com/# best online pharmacy india

buy propecia mexico best prices on finasteride in mexico amoxicillin mexico online pharmacy

best prices on finasteride in mexico: Mexican Pharmacy Hub – buy cheap meds from a mexican pharmacy

MediDirect USA: MediDirect USA – renova online pharmacy

online pharmacy india: Indian Meds One – top 10 online pharmacy in india

MediDirect USA: sainsburys pharmacy viagra – kroger pharmacy lisinopril

pharmacy website india Indian Meds One Indian Meds One

Mexican Pharmacy Hub: sildenafil mexico online – Mexican Pharmacy Hub

http://medidirectusa.com/# generic zoloft online pharmacy

Mexican Pharmacy Hub: Mexican Pharmacy Hub – legit mexican pharmacy for hair loss pills

MediDirect USA: specialty rx pharmacy – MediDirect USA

viagra pills from mexico: buy neurontin in mexico – order azithromycin mexico

best online pharmacy india indian pharmacy india pharmacy mail order

reputable indian pharmacies: indianpharmacy com – reputable indian pharmacies

viagra cost in us: buy viagra online without prescription – viagra pills without prescription

how to get viagra usa: SildenaPeak – SildenaPeak

http://kamameds.com/# Online sources for Kamagra in the United States

viagra 50 mg tablet buy online: SildenaPeak – buy viagra over the counter australia

Safe access to generic ED medication Non-prescription ED tablets discreetly shipped KamaMeds

SildenaPeak: SildenaPeak – SildenaPeak

ED treatment without doctor visits: Affordable sildenafil citrate tablets for men – Safe access to generic ED medication

sildenafil cost india: viagra pills order online – SildenaPeak

KamaMeds Safe access to generic ED medication Safe access to generic ED medication

SildenaPeak: buy viagra online without rx – price of viagra in australia

https://sildenapeak.com/# SildenaPeak

Tadalify: u.s. pharmacy prices for cialis – Tadalify

SildenaPeak: where to get viagra for women – SildenaPeak

Kamagra reviews from US customers: Kamagra reviews from US customers – Men’s sexual health solutions online

sildenafil 220 how to use viagra viagra website

cialis canada: tadalafil long term usage – Tadalify

Sildenafil oral jelly fast absorption effect: Kamagra oral jelly USA availability – ED treatment without doctor visits

Non-prescription ED tablets discreetly shipped: Non-prescription ED tablets discreetly shipped – Kamagra reviews from US customers

viagra online over the counter how to buy viagra online without prescription how to buy real viagra

91zn6u

SildenaPeak: SildenaPeak – online viagra purchase

http://tadalify.com/# Tadalify

Tadalify: cialis dapoxetine europe – Tadalify

Tadalify: Tadalify – cialis dosage 20mg

can i take two 5mg cialis at once cialis generic canada Tadalify

SildenaPeak: cialis viagra comparison – Precio de Viagra 50 mg

Tadalify: Tadalify – where to buy tadalafil in singapore

shelf life of liquid tadalafil: Tadalify – cialis premature ejaculation

SildenaPeak: discount viagra – brand viagra from canada

https://sildenapeak.shop/# generic viagra fast delivery

viagra 25 mg buy online canadian online pharmacy viagra SildenaPeak

Compare Kamagra with branded alternatives: Online sources for Kamagra in the United States – Compare Kamagra with branded alternatives

on line viagra: sildenafil 100mg price australia – how much is viagra generic

Tadalify: cialis canadian pharmacy ezzz – Tadalify

SildenaPeak: SildenaPeak – sildenafil canada price

ED treatment without doctor visits Non-prescription ED tablets discreetly shipped ED treatment without doctor visits

Compare Kamagra with branded alternatives: Sildenafil oral jelly fast absorption effect – Sildenafil oral jelly fast absorption effect

Tadalify: Tadalify – what are the side effect of cialis

https://sildenapeak.com/# sildenafil 20 mg online no prescription

Non-prescription ED tablets discreetly shipped: Online sources for Kamagra in the United States – KamaMeds

SildenaPeak SildenaPeak SildenaPeak

Non-prescription ED tablets discreetly shipped: Kamagra reviews from US customers – Kamagra reviews from US customers

SildenaPeak: buy viagra online australia – buy sildenafil 100mg online price

what doe cialis look like: Tadalify – cialis used for

Kamagra oral jelly USA availability: Kamagra oral jelly USA availability – Safe access to generic ED medication

Tadalify generic tadalafil cost prices cialis

https://kamameds.shop/# Compare Kamagra with branded alternatives

Compare Kamagra with branded alternatives: Kamagra reviews from US customers – Sildenafil oral jelly fast absorption effect

SildenaPeak: cheap sildenafil 100 – viagra purchase online

Non-prescription ED tablets discreetly shipped: Online sources for Kamagra in the United States – Sildenafil oral jelly fast absorption effect

maximum dose of tadalafil cialis online cheap cialis reviews

KamaMeds: Online sources for Kamagra in the United States – Men’s sexual health solutions online

SildenaPeak: SildenaPeak – SildenaPeak

cialis generico: cialis generic timeline 2018 – cialis buy

Kamagra reviews from US customers Fast-acting ED solution with discreet packaging ED treatment without doctor visits

viagra otc uk: SildenaPeak – buy sildenafil in canada

Online sources for Kamagra in the United States: Fast-acting ED solution with discreet packaging – Kamagra reviews from US customers

Tadalify: Tadalify – Tadalify

cost of viagra 100mg: where to buy women viagra – price of viagra 2018

Online sources for Kamagra in the United States Kamagra reviews from US customers ED treatment without doctor visits

cialis professional 20 lowest price: Tadalify – cialis black 800 mg pill house

Compare Kamagra with branded alternatives: ED treatment without doctor visits – Kamagra oral jelly USA availability

http://sildenapeak.com/# viagra price canada

canadian rx viagra: canadian pharmacy viagra 100 – SildenaPeak

SildenaPeak: sildenafil uk otc – buy discount viagra

cialis tadalafil 20mg kaufen Tadalify prices cialis

where can you buy cheap viagra: generic viagra south africa – how to get viagra for women

generic viagra australia paypal: viagra pills – SildenaPeak

0t9mfc

can i buy viagra online with paypal: SildenaPeak – SildenaPeak

Men’s sexual health solutions online: KamaMeds – Compare Kamagra with branded alternatives

https://ivergrove.com/# IverGrove

can you buy prednisone online uk prednisone 10 mg canada SteroidCare Pharmacy

CardioMeds Express: CardioMeds Express – CardioMeds Express

lasix 40mg: CardioMeds Express – furosemida

amoxicillin 500mg pill: amoxicillin buy canada – TrustedMeds Direct

prednisone buying prednisone 20mg capsule where to buy prednisone uk

FertiCare Online: FertiCare Online – FertiCare Online

lasix 100 mg tablet: CardioMeds Express – CardioMeds Express

60 mg prednisone daily: SteroidCare Pharmacy – SteroidCare Pharmacy

IverGrove: IverGrove – ivermectin iv

can i get generic clomid without dr prescription: FertiCare Online – order clomid price

lasix uses: CardioMeds Express – lasix 20 mg

TrustedMeds Direct: TrustedMeds Direct – buy amoxicillin 500mg online

where can you buy prednisone: SteroidCare Pharmacy – cheap generic prednisone

amoxicillin for sale online: amoxicillin 500 mg for sale – amoxicillin tablets in india

http://cardiomedsexpress.com/# CardioMeds Express

SteroidCare Pharmacy: SteroidCare Pharmacy – SteroidCare Pharmacy

IverGrove: IverGrove – IverGrove

kqb66e

FertiCare Online: where can i get clomid now – clomid cheap

thomas borody ivermectin: ivermectin horse paste tractor supply – IverGrove

FertiCare Online: FertiCare Online – order generic clomid

IverGrove IverGrove IverGrove

IverGrove: IverGrove – IverGrove

https://cardiomedsexpress.com/# lasix 100 mg

amoxicillin 500 mg: TrustedMeds Direct – TrustedMeds Direct

can i order cheap clomid pills: FertiCare Online – FertiCare Online

lasix 40 mg lasix for sale buy furosemide online

amoxicillin brand name: where to buy amoxicillin 500mg – amoxicillin 500 capsule

Farmacia online piГ№ conveniente: farmaci senza ricetta online – Farmacia online piГ№ conveniente

farmacia online: medicinali senza prescrizione medica – migliori farmacie online 2024

cialis farmacia senza ricetta: viagra online Italia – viagra 50 mg prezzo in farmacia

farmaci senza ricetta elenco farmacia italiana affidabile online farmacia online

viagra originale in 24 ore contrassegno: consegna discreta viagra in Italia – kamagra senza ricetta in farmacia

o0tjfy

migliori farmacie online 2024: Forza Intima – farmaci senza ricetta elenco

https://potenzafacile.com/# viagra prezzo farmacia 2023

Farmacia online miglior prezzo: sildenafil generico senza ricetta – migliori farmacie online 2024

farmacia online: ordina tadalafil da casa in Italia – farmacie online affidabili

farmacie online affidabili: accesso rapido a cialis generico online – Farmacie on line spedizione gratuita

viagra prezzo farmacia 2023 acquistare viagra generico online alternativa al viagra senza ricetta in farmacia

Farmacia online miglior prezzo: tadalafil 10mg 20mg disponibile online – farmacie online affidabili

siti sicuri per comprare viagra online: viagra online Italia – pillole per erezioni fortissime

https://forzaintima.shop/# acquistare kamagra gel online

migliori farmacie online 2024: Forza Intima – comprare farmaci online con ricetta

farmacia online senza ricetta: acquistare kamagra gel online – Farmacie online sicure

acquisto farmaci con ricetta: acquistare cialis generico online – Farmacia online miglior prezzo

п»їFarmacia online migliore consegna rapida e riservata kamagra top farmacia online

viagra generico prezzo più basso: consegna discreta viagra in Italia – siti sicuri per comprare viagra online

Farmacie on line spedizione gratuita: cialis online Italia – Farmacia online miglior prezzo

https://farmacidiretti.shop/# Farmacie online sicure

online pharmacy cytotec no prescription: MapleMeds Direct – revia pharmacy

boots pharmacy viagra price MapleMeds Direct MapleMeds Direct

mexican rx online: BorderMeds Express – BorderMeds Express

rite aid pharmacy store locator: lexapro pharmacy prices – MapleMeds Direct

safe mexican online pharmacy: safe place to buy semaglutide online mexico – BorderMeds Express

https://bharatmedsdirect.shop/# BharatMeds Direct

BharatMeds Direct BharatMeds Direct indian pharmacy paypal

MapleMeds Direct: MapleMeds Direct – pharmacy online viagra generic

BharatMeds Direct: top 10 pharmacies in india – BharatMeds Direct

BharatMeds Direct: BharatMeds Direct – buy medicines online in india

MapleMeds Direct MapleMeds Direct MapleMeds Direct

online pharmacy no prescription estradiol: pharmacy viagra prices – target pharmacy wellbutrin price

BorderMeds Express: BorderMeds Express – BorderMeds Express

https://maplemedsdirect.shop/# no prescription needed pharmacy

rx warehouse pharmacy pharmacy store in usa MapleMeds Direct

indian pharmacy paypal: BharatMeds Direct – BharatMeds Direct

MapleMeds Direct: MapleMeds Direct – MapleMeds Direct

BharatMeds Direct: online pharmacy india – BharatMeds Direct

generic drugs mexican pharmacy real mexican pharmacy USA shipping BorderMeds Express

best online pharmacies in mexico: best online pharmacies in mexico – best mexican online pharmacies

BharatMeds Direct: reputable indian online pharmacy – BharatMeds Direct

BharatMeds Direct: BharatMeds Direct – pharmacy website india

https://bharatmedsdirect.shop/# BharatMeds Direct

2ynrft

online pharmacy india BharatMeds Direct best india pharmacy

rx pharmacy meaning: Cialis Soft Tabs – metronidazole cream online pharmacy

MapleMeds Direct: reputable viagra online pharmacy – MapleMeds Direct

isotretinoin from mexico: buy modafinil from mexico no rx – accutane mexico buy online

Aktywacja kodów daje dodatkowe bonusy, takie jak darmowe spiny lub dodatkowe pieniądze. Kody można uzyskać od zespołu wsparcia, w mediach społecznościowych, e-mailem lub w wiadomościach w profilu gracza.

india pharmacy mail order indian pharmacy paypal BharatMeds Direct

viagra internet pharmacy: MapleMeds Direct – lansoprazole pharmacy

relenza online pharmacy: boot pharmacy store locator – MapleMeds Direct

MapleMeds Direct: cialis web pharmacy – MapleMeds Direct

https://bordermedsexpress.shop/# BorderMeds Express

rybelsus from mexican pharmacy BorderMeds Express BorderMeds Express

BorderMeds Express: get viagra without prescription from mexico – BorderMeds Express

MapleMeds Direct: provigil internet pharmacy – micardis online pharmacy

mail order pharmacy india: Online medicine home delivery – BharatMeds Direct

BharatMeds Direct pharmacy website india india pharmacy

BorderMeds Express: legit mexico pharmacy shipping to USA – safe place to buy semaglutide online mexico

buying from online mexican pharmacy: BorderMeds Express – medicine in mexico pharmacies

preman69 situs judi online 24 jam: preman69 login – preman69 login

preman69 situs judi online 24 jam: promosi dan bonus harian preman69 – 1win69

https://1wbook.com/# book of ra deluxe

garuda888 login resmi tanpa ribet garuda888 garuda888 game slot RTP tinggi

bonaslot jackpot harian jutaan rupiah: bonaslot kasino online terpercaya – bonaslot

migliori casino online con Starburst: starburst – starburst

It’s the best time to make some plans for the future and it is time to be happy. I have read this post and if I could I want to suggest you few interesting things or suggestions. Perhaps you could write next articles referring to this article. I wish to read more things about it!

agen garuda888 bonus new member: link alternatif garuda888 terbaru – daftar garuda888 mudah dan cepat

garuda888 garuda888 live casino Indonesia permainan slot gacor hari ini

https://1wbook.com/# Book of Ra Deluxe soldi veri

preman69: preman69 situs judi online 24 jam – 1win69

bonaslot link resmi mudah diakses: bonaslot link resmi mudah diakses – bonaslot situs bonus terbesar Indonesia

recensioni Book of Ra Deluxe slot book of ra deluxe migliori casino online con Book of Ra

rxdwwb

Book of Ra Deluxe slot online Italia: giri gratis Book of Ra Deluxe – giri gratis Book of Ra Deluxe

garuda888 slot online terpercaya: garuda888 login resmi tanpa ribet – garuda888

link alternatif garuda888 terbaru: 1win888indonesia – garuda888 live casino Indonesia

migliori casino online con Book of Ra book of ra deluxe Book of Ra Deluxe soldi veri

https://1wbook.shop/# recensioni Book of Ra Deluxe slot

Book of Ra Deluxe slot online Italia: recensioni Book of Ra Deluxe slot – book of ra deluxe

starburst: migliori casino online con Starburst – Starburst slot online Italia

garuda888 game slot RTP tinggi: garuda888 slot online terpercaya – link alternatif garuda888 terbaru

giri gratis Book of Ra Deluxe bonus di benvenuto per Book of Ra Italia Book of Ra Deluxe slot online Italia

bonaslot jackpot harian jutaan rupiah: bonaslot jackpot harian jutaan rupiah – 1wbona

preman69 login tanpa ribet: promosi dan bonus harian preman69 – slot gacor hari ini preman69

preman69 situs judi online 24 jam slot gacor hari ini preman69 preman69 login

https://1wstarburst.shop/# casino online sicuri con Starburst

1win69: promosi dan bonus harian preman69 – preman69 login

giri gratis Book of Ra Deluxe: book of ra deluxe – bonus di benvenuto per Book of Ra Italia

bonaslot: bonaslot – bonaslot

VitalCore Pharmacy: ed pills – ed pills

VitalCore Pharmacy: VitalCore – VitalCore Pharmacy

https://vitalcorepharm.shop/# VitalCore

https://clearmedspharm.com/#

ClearMeds Pharmacy ClearMeds Pharmacy buy antibiotics for tooth infection

: – ClearMeds

cheap antibiotics: cheap antibiotics – cheap antibiotics

https://clearmedspharm.shop/# buy antibiotics online for uti

VitalCore Pharmacy VitalCore Pharmacy VitalCore

TrueMeds Pharmacy: compare pharmacy prices – TrueMeds Pharmacy

TrueMeds: TrueMeds Pharmacy – TrueMeds Pharmacy

http://vitalcorepharm.com/# ed meds online

ClearMeds ClearMeds Pharmacy ClearMeds

ClearMeds: buy antibiotics online safely – cheap antibiotics

https://truemedspharm.shop/# TrueMeds Pharmacy

ClearMeds Pharmacy: buy antibiotics online safely – buy antibiotics online

cheapest ed meds VitalCore Pharmacy VitalCore

ed pills: ed pills – ed pills

https://clearmedspharm.shop/# buy antibiotics online

TrueMeds: TrueMeds Pharmacy – canadian pharmacy

http://clearmedspharm.com/# buy antibiotics for tooth infection

global pharmacy TrueMeds TrueMeds

buy antibiotics online safely: buy antibiotics –

http://clearmedspharm.com/# ClearMeds

Amazing blog! Do you have any hints for aspiring writers? I’m hoping to start my own site soon but I’m a little lost on everything. Would you advise starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m totally confused .. Any recommendations? Thank you!

Greetings I am so thrilled I found your webpage, I really found you by accident, while I was researching on Yahoo for something else, Nonetheless I am here now and would just like to say thank you for a tremendous post and a all round exciting blog (I also love the theme/design), I don’t have time to browse it all at the moment but I have book-marked it and also added in your RSS feeds, so when I have time I will be back to read a lot more, Please do keep up the great job.

ed online pharmacy: ed pills – VitalCore

pilule bleue en ligne: viagra femme – Viagra vente libre allemagne

cialis generique pas cher commander cialis discretement IntimaPharma

tadalafil 20 mg en ligne: IntimaPharma – médicament contre la dysfonction érectile

https://bluepharmafrance.shop/# viagra 100 mg prix abordable France

pharmacie en ligne: medicaments generiques et originaux France – pharmacie en ligne pas cher

IntimaPharma medicament contre la dysfonction erectile Intima Pharma

IntimaPharma France: IntimaPharma France – IntimaPharma

pharmacie en ligne fiable: cialis generique pas cher – cialis sans ordonnance

kamagra oral jelly kamagra 100 mg prix competitif en ligne PharmaLibre France

https://intimapharmafrance.shop/# commander cialis discretement

acheter kamagra pas cher livraison rapide: PharmaLibre France – kamagra

https://intimapharmafrance.shop/# IntimaPharma France

PharmaExpress: pharmacie digitale francaise fiable – pharmacies en ligne certifiГ©es

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You definitely know what youre talking about, why throw away your intelligence on just posting videos to your blog when you could be giving us something enlightening to read?

https://pharmalibrefrance.com/# PharmaLibre France

commander medicaments livraison rapide: pharmacie en ligne france fiable – Pharmacie Internationale en ligne

I discovered your weblog web site on google and check a couple of of your early posts. Continue to keep up the excellent operate. I simply further up your RSS feed to my MSN Information Reader. Looking for ahead to studying extra from you afterward!?

cialis original et generique livraison rapide cialis generique pas cher cialis generique pas cher

https://pharmalibrefrance.com/# commander kamagra en toute confidentialite

https://bluepharmafrance.shop/# BluePharma

tadalafil sans ordonnance: pharmacie en ligne – commander cialis discretement

tadalafil sans ordonnance pharmacie en ligne sans ordonnance IntimaPharma France

bataraslot: situs slot batara88 – batara88

https://linklist.bio/inatogelbrand# inatogel 4D

Official Link Situs Toto Togel Login Alternatif Togel Situs Togel Terpercaya Dan Bandar

https://linklist.bio/inatogelbrand# Official Link Situs Toto Togel

Thanks for the ideas you have contributed here. Moreover, I believe there are some factors that keep your car insurance premium all the way down. One is, to take into consideration buying cars that are inside the good set of car insurance corporations. Cars which can be expensive tend to be at risk of being robbed. Aside from that insurance is also good value of your car or truck, so the more pricey it is, then higher the actual premium you have to pay.

toto slot hargatoto: hargatoto – toto slot hargatoto

inatogel 4D Official Link Situs Toto Togel Situs Togel Terpercaya Dan Bandar

betawi77 login: betawi77 net – betawi77 net

https://tap.bio/@hargatoto# hargatoto login

batara vip: batara88 – batarabet login

ddwxzm

Login Alternatif Togel Situs Togel Toto 4D Situs Togel Terpercaya Dan Bandar

bataraslot: situs slot batara88 – batarabet alternatif

https://linkr.bio/betawi777# betawi 77 slot

I love your wordpress web template, where did you down load it from?

https://linktr.ee/mawartotol# mawartoto alternatif

inatogel inatogel 4D INA TOGEL Daftar

situs slot batara88: bataraslot alternatif – situs slot batara88

betawi77 net betawi 777 betawi77 net

Hi are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you need any html coding knowledge to make your own blog? Any help would be really appreciated!

mawartoto: mawartoto – mawartoto slot

betawi77 link alternatif betawi 777 betawi77 link alternatif

kratonbet alternatif: kratonbet – kratonbet alternatif

https://mez.ink/batarabet# batara vip

mawartoto alternatif mawartoto login mawartoto link

mawartoto link: mawartoto slot – mawartoto alternatif

bataraslot situs slot batara88 bataraslot

inatogel 4D: inatogel – Official Link Situs Toto Togel

What?s Taking place i am new to this, I stumbled upon this I’ve discovered It positively helpful and it has aided me out loads. I hope to contribute & assist other users like its helped me. Great job.

Daftar InaTogel Login Link Alternatif Terbaru Situs Togel Toto 4D Daftar InaTogel Login Link Alternatif Terbaru

cialis stopped working: cialis canada sale – free samples of cialis

cialis with out a prescription order cialis soft tabs tadalafil no prescription forum

EverGreenRx USA: cialis for sale – EverGreenRx USA

https://evergreenrxusas.shop/# tadalafil medication

EverGreenRx USA: EverGreenRx USA – EverGreenRx USA

cialis used for EverGreenRx USA EverGreenRx USA

cialis generic cost: generic tadalafil cost – cialis online delivery overnight

http://evergreenrxusas.com/# EverGreenRx USA

https://evergreenrxusas.shop/# compounded tadalafil troche life span

cheapest 10mg cialis: adcirca tadalafil – cialis slogan

EverGreenRx USA EverGreenRx USA EverGreenRx USA

tadalafil (megalis-macleods) reviews: EverGreenRx USA – peptide tadalafil reddit

https://evergreenrxusas.shop/# EverGreenRx USA

sildenafil tablets online order UK http://mediquickuk.com/# confidential delivery pharmacy UK

order viagra online safely UK fast delivery viagra UK online BluePillUK

https://mediquickuk.shop/# trusted UK digital pharmacy

https://meditrustuk.shop/# MediTrust UK

IntimaCare UK: branded and generic tadalafil UK pharmacy – branded and generic tadalafil UK pharmacy

Hi, Neat post. There is a problem with your website in internet explorer, would check this? IE still is the market leader and a good portion of people will miss your excellent writing due to this problem.

generic sildenafil UK pharmacy http://intimacareuk.com/# IntimaCare

i9tigb

stromectol pills home delivery UK generic stromectol UK delivery MediTrust UK

http://bluepilluk.com/# sildenafil tablets online order UK

generic stromectol UK delivery: MediTrustUK – stromectol pills home delivery UK

generic sildenafil UK pharmacy https://mediquickuk.com/# pharmacy online fast delivery UK

https://intimacareuk.com/# IntimaCare UK

MediQuickUK generic and branded medications UK MediQuick UK

https://mediquickuk.shop/# MediQuick UK

I’m really enjoying the theme/design of your web site. Do you ever run into any web browser compatibility problems? A couple of my blog audience have complained about my site not operating correctly in Explorer but looks great in Chrome. Do you have any solutions to help fix this issue?

I can’t express how much I value the effort the author has put into producing this exceptional piece of content. The clarity of the writing, the depth of analysis, and the plethora of information provided are simply impressive. His enthusiasm for the subject is obvious, and it has definitely struck a chord with me. Thank you, author, for sharing your wisdom and enhancing our lives with this extraordinary article!

generic sildenafil UK pharmacy https://intimacareuk.shop/# buy ED pills online discreetly UK

IntimaCare UK tadalafil generic alternative UK cialis online UK no prescription

MediQuickUK: order medicines online discreetly – generic and branded medications UK

viagra discreet delivery UK https://bluepilluk.com/# BluePillUK

cialis online UK no prescription confidential delivery cialis UK confidential delivery cialis UK

https://meditrustuk.shop/# trusted online pharmacy ivermectin UK

trusted online pharmacy ivermectin UK: ivermectin cheap price online UK – generic stromectol UK delivery

sildenafil tablets online order UK https://bluepilluk.com/# sildenafil tablets online order UK

confidential delivery cialis UK branded and generic tadalafil UK pharmacy IntimaCare

Aw, this was a very nice post. In idea I wish to put in writing like this additionally ? taking time and precise effort to make an excellent article? but what can I say? I procrastinate alot and on no account seem to get one thing done.

MediQuick UK: MediQuickUK – trusted UK digital pharmacy

srmz9m

MediTrust UK discreet ivermectin shipping UK MediTrust UK

cialis online UK no prescription: weekend pill UK online pharmacy – branded and generic tadalafil UK pharmacy

https://meditrustuk.com/# ivermectin without prescription UK

tadalafil generic alternative UK weekend pill UK online pharmacy IntimaCare

safe ivermectin pharmacy UK: MediTrust – discreet ivermectin shipping UK

weekend pill UK online pharmacy IntimaCare branded and generic tadalafil UK pharmacy

cialis cheap price UK delivery: buy ED pills online discreetly UK – IntimaCare UK

http://mediquickuk.com/# confidential delivery pharmacy UK

http://saludfrontera.com/# medicine from mexico

TrueNorth Pharm: TrueNorth Pharm – canadian pharmacy no scripts

mexican drugstore online pharmacy in mexico the purple pharmacy mexico

oxycontin india: CuraBharat USA – CuraBharat USA

https://truenorthpharm.com/# canadian pharmacy world

http://truenorthpharm.com/# TrueNorth Pharm

TrueNorth Pharm: TrueNorth Pharm – pet meds without vet prescription canada

SaludFrontera [url=http://saludfrontera.com/#]SaludFrontera[/url] SaludFrontera

dn4esv

Thank you, I’ve recently been looking for info about this topic for a while and yours is the best I’ve discovered till now. But, what concerning the conclusion? Are you certain in regards to the supply?

Great work! That is the kind of info that should be shared around the internet. Disgrace on Google for not positioning this put up higher! Come on over and discuss with my website . Thank you =)

Someone necessarily assist to make critically articles I would state. That is the very first time I frequented your website page and thus far? I amazed with the research you made to create this actual put up extraordinary. Wonderful process!

TrueNorth Pharm: pharmacies in canada that ship to the us – TrueNorth Pharm

http://saludfrontera.com/# mexipharmacy reviews

CuraBharat USA: indian medicines in usa – CuraBharat USA

ntlczx

п»їindian pharmacy: CuraBharat USA – CuraBharat USA

ordering drugs from canada TrueNorth Pharm TrueNorth Pharm

http://truenorthpharm.com/# canadian pharmacy world reviews

TrueNorth Pharm: TrueNorth Pharm – TrueNorth Pharm

canadian pharmacy meds review: TrueNorth Pharm – vipps canadian pharmacy

pharmacys in mexico pharmacies in mexico that ship to the us mexican drugstore

https://curabharatusa.shop/# india rx

I’m not that much of a online reader to be honest but your blogs really nice, keep it up! I’ll go ahead and bookmark your website to come back down the road. Many thanks

ajy6vv

SaludFrontera: SaludFrontera – farmacia online usa

http://saludfrontera.com/# mexican pharmacy las vegas

TrueNorth Pharm: TrueNorth Pharm – canadian neighbor pharmacy

online chemists CuraBharat USA how to purchase medicine online

I know this if off topic but I’m looking into starting my own weblog and was curious what all is required to get set up? I’m assuming having a blog like yours would cost a pretty penny? I’m not very internet savvy so I’m not 100 sure. Any recommendations or advice would be greatly appreciated. Cheers

Thanks for your article. I have generally seen that a majority of people are wanting to lose weight simply because they wish to show up slim and also attractive. Having said that, they do not often realize that there are additional benefits for you to losing weight in addition. Doctors insist that over weight people come across a variety of health conditions that can be directly attributed to their particular excess weight. Fortunately that people who’re overweight as well as suffering from various diseases are able to reduce the severity of their illnesses simply by losing weight. You possibly can see a steady but noticeable improvement in health while even a slight amount of losing weight is realized.

SaludFrontera: mexican drugstore – SaludFrontera

CuraBharat USA: CuraBharat USA – order adderall from india

http://curabharatusa.com/# CuraBharat USA

TrueNorth Pharm TrueNorth Pharm online canadian drugstore

http://truenorthpharm.com/# canadian pharmacy no scripts

pharmacy delivery: online mexican pharmacies – online pharmacies

https://curabharatusa.com/# online medicine india

canadian pharmacy online ship to usa TrueNorth Pharm onlinecanadianpharmacy

I?d have to verify with you here. Which is not something I usually do! I get pleasure from reading a publish that may make folks think. Additionally, thanks for permitting me to remark!

generisches sildenafil alternative: kamagra erfahrungen deutschland – Viagra wie lange steht er

ohne rezept apotheke: rezeptfreie arzneimittel online kaufen – gГјnstigste online apotheke

http://gesunddirekt24.com/# online apotheke rezept

I would like to thnkx for the efforts you have put in writing this blog. I’m hoping the same high-grade website post from you in the upcoming also. Actually your creative writing abilities has inspired me to get my own blog now. Actually the blogging is spreading its wings rapidly. Your write up is a good example of it.

online apotheke gГјnstig diskrete lieferung von potenzmitteln ohne rezept apotheke

https://potenzapothekede.com/# cialis generika ohne rezept

europa apotheke: blaue pille erfahrungen manner – online apotheke

ohne rezept apotheke: deutsche online apotheke erfahrungen – europa apotheke

https://gesunddirekt24.shop/# online apotheke rezept

Thanks for the sensible critique. Me and my neighbor were just preparing to do some research on this. We got a grab a book from our area library but I think I learned more clear from this post. I am very glad to see such fantastic information being shared freely out there.

whoah this blog is great i love reading your articles. Keep up the good work! You know, lots of people are looking around for this info, you can help them greatly.

medikamente rezeptfrei rezeptfreie arzneimittel online kaufen apotheke online

kamagra kaufen ohne rezept online: kamagra erfahrungen deutschland – In welchen europГ¤ischen LГ¤ndern ist Viagra frei verkГ¤uflich

Hello my loved one! I wish to say that this post is awesome, nice written and include almost all significant infos. I?d like to look more posts like this .

PotenzApotheke: tadalafil 20mg preisvergleich – apotheke online

Wonderful work! This is the type of information that should be shared around the web. Shame on Google for not positioning this post higher! Come on over and visit my website . Thanks =)

apotheke online sildenafil tabletten online bestellen online apotheke preisvergleich

Thanks for your post. What I want to say is that when you are evaluating a good on the web electronics go shopping, look for a web page with total information on critical factors such as the level of privacy statement, basic safety details, payment options, and various terms along with policies. Always take time to investigate the help along with FAQ sections to get a superior idea of what sort of shop performs, what they can do for you, and in what way you can maximize the features.

http://intimgesund.com/# kamagra oral jelly deutschland bestellen

kamagra kaufen ohne rezept online: kamagra erfahrungen deutschland – Viagra online kaufen legal in Deutschland

shop apotheke gutschein: internet apotheke – online apotheke versandkostenfrei

https://potenzapothekede.com/# wirkung und dauer von tadalafil

eu apotheke ohne rezept Manner Kraft online apotheke

I?ll right away grasp your rss feed as I can not in finding your e-mail subscription link or e-newsletter service. Do you have any? Please permit me realize so that I may subscribe. Thanks.

Intim Gesund: kamagra kaufen ohne rezept online – Viagra online kaufen legal Г–sterreich

europa apotheke: sicherheit und wirkung von potenzmitteln – beste online-apotheke ohne rezept

internet apotheke internet apotheke ohne rezept apotheke

internet apotheke: sicherheit und wirkung von potenzmitteln – gГјnstigste online apotheke

https://gesunddirekt24.shop/# internet apotheke

http://intimgesund.com/# kamagra erfahrungen deutschland

günstigste online apotheke: günstige medikamente direkt bestellen – online apotheke versandkostenfrei

lz0a17

Thanks for your posting. I also think laptop computers have grown to be more and more popular right now, and now are often the only type of computer utilised in a household. This is due to the fact that at the same time that they’re becoming more and more economical, their working power keeps growing to the point where they may be as robust as desktop through just a few years back.

ohne rezept apotheke rezeptfreie medikamente fur erektionsstorungen tadalafil erfahrungen deutschland

online apotheke deutschland: generika potenzmittel online bestellen – online apotheke versandkostenfrei

online apotheke preisvergleich: sildenafil tabletten online bestellen – internet apotheke

https://potenzapothekede.com/# tadalafil 20mg preisvergleich

generisches sildenafil alternative: kamagra oral jelly deutschland bestellen – Viagra rezeptfreie LГ¤nder

https://blaukraftde.com/# online apotheke gГјnstig

günstige online apotheke: GesundDirekt24 – apotheke online

internet apotheke gunstige medikamente direkt bestellen eu apotheke ohne rezept

Simply wish to say your article is as amazing. The clarity in your post is just great and i can assume you’re an expert on this subject. Well with your permission let me to grab your RSS feed to keep up to date with forthcoming post. Thanks a million and please keep up the enjoyable work.

Thanks for the concepts you discuss through this blog. In addition, many young women which become pregnant will not even seek to get medical care insurance because they worry they won’t qualify. Although some states today require that insurers produce coverage despite the pre-existing conditions. Prices on all these guaranteed programs are usually higher, but when thinking about the high cost of medical treatment it may be the safer approach to take to protect a person’s financial potential.

Have you ever considered writing an ebook or guest authoring on other websites? I have a blog based upon on the same ideas you discuss and would love to have you share some stories/information. I know my visitors would appreciate your work. If you’re even remotely interested, feel free to send me an e mail.

online apotheke gГјnstig: blaue pille erfahrungen manner – online apotheke preisvergleich

I truly appreciate this post. I?ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

I appreciate, result in I found exactly what I used to be having a look for. You’ve ended my four day lengthy hunt! God Bless you man. Have a great day. Bye

https://blaukraftde.shop/# apotheke online

Excellent read, I just passed this onto a friend who was doing some research on that. And he just bought me lunch since I found it for him smile Therefore let me rephrase that: Thank you for lunch!

ClearMedsHub: ClearMedsHub – Clear Meds Hub

I was wondering if you ever considered changing the layout of your site? Its very well written; I love what youve got to say. But maybe you could a little more in the way of content so people could connect with it better. Youve got an awful lot of text for only having 1 or 2 images. Maybe you could space it out better?

Together with almost everything which seems to be building inside this area, all your viewpoints happen to be very refreshing. Having said that, I am sorry, because I can not give credence to your whole strategy, all be it stimulating none the less. It would seem to everybody that your opinions are generally not totally rationalized and in reality you are your self not entirely certain of your argument. In any case I did enjoy examining it.

https://vitaledgepharma.com/# VitalEdge Pharma

Ever Trust Meds: EverTrustMeds – Ever Trust Meds

https://clearmedshub.shop/#

Ever Trust Meds EverTrustMeds EverTrustMeds

Ever Trust Meds: Ever Trust Meds – EverTrustMeds

I’ve been surfing online more than three hours today, yet I never found any interesting article like yours. It?s pretty worth enough for me. In my view, if all website owners and bloggers made good content as you did, the internet will be a lot more useful than ever before.

Clear Meds Hub: ClearMedsHub – ClearMedsHub

https://clearmedshub.shop/# ClearMedsHub

https://evertrustmeds.com/# Buy Tadalafil 10mg

VitalEdgePharma where to get ed pills VitalEdgePharma

Thanks for the helpful article. It is also my opinion that mesothelioma has an very long latency period of time, which means that indication of the disease may not emerge right until 30 to 50 years after the initial exposure to asbestos. Pleural mesothelioma, that is the most common style and impacts the area round the lungs, will cause shortness of breath, upper body pains, as well as a persistent coughing, which may result in coughing up maintain.

Thanks , I’ve just been looking for info about this subject for ages and yours is the greatest I have discovered so far. But, what about the conclusion? Are you sure about the source?

VitalEdgePharma: where to buy ed pills – VitalEdge Pharma

wonderful points altogether, you just gained a new reader. What could you recommend in regards to your post that you simply made a few days in the past? Any certain?

Tadalafil price: Ever Trust Meds – Ever Trust Meds

Thanks on your marvelous posting! I definitely enjoyed reading it, you can be a great author.I will always bookmark your blog and will eventually come back sometime soon. I want to encourage you continue your great writing, have a nice weekend!

Segera laporkan situs tidak aman ini.

Não deixe essa fraude continuar, denuncie.

very good publish, i actually love this website, keep on it

ClearMedsHub

Thanks for the guidelines shared in your blog. Something else I would like to express is that weight loss is not about going on a dietary fads and trying to lose as much weight as you can in a few days. The most effective way to lose weight naturally is by using it slowly and using some basic ideas which can make it easier to make the most from a attempt to shed weight. You may be aware and already be following a few of these tips, but reinforcing know-how never hurts.

Thanks for the ideas shared on the blog. Something also important I would like to mention is that weight loss is not information on going on a fad diet and trying to shed as much weight that you can in a few months. The most effective way to lose weight is by having it slowly and using some basic tips which can enable you to make the most through your attempt to lose fat. You may know and be following many of these tips, although reinforcing information never does any damage.

Thank you for another wonderful post. Where else could anybody get that type of information in such a perfect way of writing? I have a presentation next week, and I’m on the look for such information.

: – Clear Meds Hub

http://vitaledgepharma.com/# VitalEdge Pharma

What an informative and thoroughly-researched article! The author’s meticulousness and aptitude to present intricate ideas in a digestible manner is truly admirable. I’m thoroughly impressed by the breadth of knowledge showcased in this piece. Thank you, author, for sharing your wisdom with us. This article has been a real game-changer!

Clear Meds Hub: ClearMedsHub – ClearMedsHub

https://vitaledgepharma.com/# VitalEdgePharma

Wonderful beat ! I would like to apprentice even as you amend your web site, how can i subscribe for a blog website? The account aided me a appropriate deal. I were a little bit familiar of this your broadcast provided vivid clear concept

VitalEdge Pharma VitalEdge Pharma VitalEdgePharma

Its like you read my mind! You appear to understand so much about this, such as you wrote the ebook in it or something. I think that you can do with some p.c. to drive the message home a bit, but other than that, this is magnificent blog. An excellent read. I will certainly be back.

Hello my friend! I wish to say that this article is awesome, nice written and come with almost all vital infos. I would like to peer extra posts like this .

Hi there! I know this is kinda off topic however I’d figured I’d ask. Would you be interested in trading links or maybe guest writing a blog post or vice-versa? My website covers a lot of the same topics as yours and I think we could greatly benefit from each other. If you happen to be interested feel free to send me an e-mail. I look forward to hearing from you! Fantastic blog by the way!

VitalEdge Pharma: VitalEdgePharma – best online ed pills

http://evertrustmeds.com/# Cheap Cialis

cheap boner pills: VitalEdge Pharma – ed meds online

Thanks on your marvelous posting! I truly enjoyed reading it, you happen to be a great author.I will make certain to bookmark your blog and definitely will come back later in life. I want to encourage you to ultimately continue your great writing, have a nice day!

VitalEdgePharma VitalEdgePharma ed medicines

Ever Trust Meds: Ever Trust Meds – Ever Trust Meds

https://clearmedshub.com/# ClearMedsHub

Ever Trust Meds: EverTrustMeds – EverTrustMeds

https://clearmedshub.com/#

ClearMedsHub

I like the valuable info you provide in your articles. I will bookmark your weblog and check again here regularly. I’m quite sure I?ll learn plenty of new stuff right here! Good luck for the next!

Good blog post. A few things i would like to bring up is that personal computer memory has to be purchased if your computer still cannot cope with everything you do by using it. One can mount two good old ram boards of 1GB each, by way of example, but not one of 1GB and one with 2GB. One should look for the manufacturer’s documentation for the PC to ensure what type of storage is essential.

https://vitaledgepharma.shop/# VitalEdge Pharma

Ever Trust Meds: EverTrustMeds – EverTrustMeds

That is the proper blog for anybody who needs to search out out about this topic. You notice so much its nearly hard to argue with you (not that I actually would need?HaHa). You positively put a new spin on a subject thats been written about for years. Great stuff, simply great!

Saya kagum dengan hasilnya.

cheapest online ed treatment ed pills cheap cheapest online ed meds

Truly above average.

Good day! This is my first visit to your blog! We are a collection of volunteers and starting a new project in a community in the same niche. Your blog provided us valuable information to work on. You have done a extraordinary job!

This site is always consistent.

buy erectile dysfunction treatment: VitalEdgePharma – VitalEdgePharma

Thanks for your helpful post. As time passes, I have been able to understand that the actual symptoms of mesothelioma cancer are caused by a build up connected fluid between the lining in the lung and the breasts cavity. The illness may start inside chest region and pass on to other areas of the body. Other symptoms of pleural mesothelioma include weight reduction, severe breathing trouble, vomiting, difficulty taking in food, and puffiness of the neck and face areas. It ought to be noted that some people with the disease usually do not experience any kind of serious indicators at all.

You could certainly see your enthusiasm in the work you write. The world hopes for even more passionate writers like you who are not afraid to say how they believe. Always go after your heart.

Cialis 20mg price: Buy Cialis online – Buy Tadalafil 20mg

https://clearmedshub.shop/#

F*ckin? tremendous things here. I am very glad to see your article. Thanks a lot and i am looking forward to contact you. Will you kindly drop me a e-mail?

Nice post. I was checking constantly this weblog and I’m inspired! Extremely useful info specifically the last section 🙂 I take care of such information much. I was looking for this certain information for a very lengthy time. Thank you and best of luck.

https://clearmedshub.shop/# Clear Meds Hub

Clear Meds Hub ClearMedsHub

VitalEdgePharma: cheap ed pills – VitalEdge Pharma

: Clear Meds Hub – Clear Meds Hub

http://evertrustmeds.com/# EverTrustMeds

EverTrustMeds Ever Trust Meds Ever Trust Meds

ClearMedsHub: ClearMedsHub – ClearMedsHub